Sub Arc Welding Wires

Submerged arc welding is the preferred mode of welding for long straight seams, shipbuilding industries, oil and gas refineries, fabrication of LPG cylinders & bridge girders and rotated pipes or vessels. Venus Wires Industries Pvt. Ltd. produces excellent sub arc weld wires for the enhanced performance of continuous arc welding. Precision diameter tolerance of our wires makes the job easy for an arc welder. Our SS wires offer superior weld quality and fully comply with the specifications of American Welding Society (AWS). The welding wires manufactured by us are suitable for both automatic submerged arc welding machines and hand operated SAW guns. Our welding wires are manufactured for SS grades, AISI 307, 307Si, 308, 308H, 308L, 308LSi, 309, 309L, 309LSi, 309LMo, 310, 312, 316, 316H, 316L, 316LSi, 317, 317Si, 318Si, 321, 347, 347Si, 409, 409Cb, 409Ti, 410, 410NiMo, 420, 430, 430LNb, 904L, and 2209.

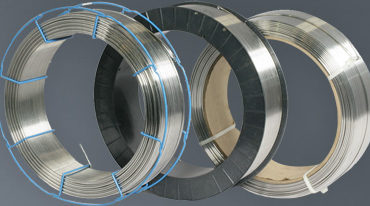

While the cross sectional diameter of our SS core wires range from 1.60 to 4.00 mm, the length is maintained as per the weight requirement of client specification. Again the wire is packed either in layer wound coils of 25 Kg or spooled in baskets (K415) or plastic (H400).

Venus Industries guarantees that SAW SS wires helps develop by them will provides yields delivers the most advanced and productive welding products.

For SAW Process

Diameter

| mm | 1.60 | 2.00 | 2.40 | 3.20 | 4.00 |

|---|---|---|---|---|---|

| Inch | 0.062 | 0.080 | 0.093 | 0.125 | 0.156 |

Grades

307Si, 308L, 308LSi, 309L, 309LSi, 309LMo, 310, 312, 316L, 316LSi, 317, 317L, 318Si, 321, 347, 347Si, 409, 409Cb, 409Ti, 410, 410NiMo, 420, 430, 430LNb, 904L, 2209, 2594, 630, NiCr-3, NiCrMo-3

Reviews

There are no reviews yet.